Maturity and Quality

Cantaloupes are harvested by maturity and not by size. Commercial maturity is ideally at the firm-ripe stage or "3/4 to full-slip" when a clear abscission (slip, separation) from the vine occurs with light pressure. Cantaloupes ripen after harvest but do not increase in sugar content (see below).

Cultivars vary in their external color at this stage of maturity and may retain a greenish cast. This skin color typically transitions from gray to dull green when immature, deep uniform green at maturity, and light yellow at full ripeness. A raised and well-rounded netting on the fruit surface is another indicator of proper commercial maturity.

- Well-shaped nearly spherical and uniform in appearance

- Smooth stem end with no adhering peduncle (stem-attachment) which suggests premature harvest

- Absence of scars, sunburn or surface defects

- Firm with no evidence of bruising or excessive scuffing

- Appears heavy for size and has firm internal cavity without loose seeds or liquid accumulation

U.S. grades are Fancy, No. 1, Commercial and No. 2. Distinction among grades is based predominantly on external appearances and measured soluble solids. Federal Grade Standards specify a minimum of 11% soluble solids for U.S. Fancy ("Very good internal quality") and 9% soluble solids for U.S. 1 ("Good internal quality"). A calibrated refractometer, measuring °Brix, is accepted as the current standard for soluble solids measurements.

Sizing is based on count per 18.2 kg (40 lb.) container, most typically 9, 12, 15 and occasionally 18 or 23 melons per carton. An 18 to 45 count crate may also be used.

Postharvest Handling and Storage

2.2°C-5°C (36°F-41°F) Storage life is up to 21 days at 2.2°C (36°F) but sensory quality may be reduced. Typically 12-15 days of shelf life are attainable within the optimum range. Short term storage or transit temperatures below this range are used by some in the trade but may result in chilling injury after several days [for example,7 days or longer at temperatures below 2.2°C (36°F)].

| Temperature | 0°C | 5°C | 10°C | 15°C | 20°C | 25°C |

|---|---|---|---|---|---|---|

| (32°F) | (41°F) | (50°F) | (59°F) | (68°F) | (77°F) | |

| ml CO2/kg·hr | 2-3NR | 4-5 | 7-8 | 17-20 | 23-33 | 65-71 |

To calculate heat production multiply ml CO2/kg·hr by 440 to get Btu/ton/ day or by 122 to get kcal/metric ton/day.

NR - not recommended for more than a few days due to chilling injury.

Cantaloupes are moderately sensitive to exogenous ethylene and over-ripening may be a problem during distribution and short-term storage.

90%-95%; High relative humidity is essential to maximize postharvest quality and prevent desiccation. Water loss through scuffed and damaged surface netting can be significant. Extended periods of higher humidity or condensation may encourage the growth of stem-scar and surface molds.

Intact fruit: 40 - 80 µl/kg·hr at 20°C (68°F)

Production Fresh-cut: - 7-10 µl/kg·hr at 5°C (41°F)

Controlled atmosphere storage or shipping offer only moderate benefits for cantaloupes under most conditions. With extended transit times (14-21 Atmospheres (CA) days), cantaloupes are reported to benefit from delayed ripening, reduced respiration and associated sugar loss, and inhibition of surface molds and decay. Consensus atmospheres of 3% O2 and 10% CO2 at 3°C (37.4°F) has been demonstrated. Elevated CO2 at 10-20% is tolerated but will cause effervescence in the fruit flesh. This carbonated flavor is lost on transfer to air.

Low O2 (<1%) or high CO2 (> 20%) will cause impaired ripening, off-flavors and odors, and other condition defects.

Disorders

Chilling injury. Typically occurs after storage at temperatures < 2°C Disorders (35.6°F) for several days. Sensitivity to chilling injury decreases as melon maturity and ripeness increases. Symptoms of chilling injury include pitting or sunken areas, failure to ripen, off-flavors and increased surface decay.

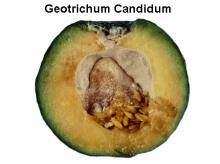

Disease can be an important source of postharvest loss depending on season, region and handling practices. Commonly, decay or surface lesions result from the fungal pathogens Alternaria, Penicillium, Cladosporium, Geotrichum, Rhizopus, and to a lesser extent Mucor. Treatment with hot air or hot water immersion (55°C for 0.5-1.0 min.) has been effective in preventing surface mold but has not been used extensively for commercial treatments. CA can be effective in delaying fungal growth on the stem-end and fruit surface.

Special Considerations Rapid precooling soon after harvest is essential for optimal postharvest keeping quality. The precooling endpoint is typically 10°C (50°F) but 4°C (39.2°F) is more desirable. Forced-air cooling is the most common practice but Hydrocooling is also utilized.

[For more information, see our publication "Fruit Ripening and Ethylene Management", available for purchase using our Publication order.]