Thompson, J., A. Kader, and K. Sylva. 1996. Compatibility chart for fruits and vegetables in short-term transport or storage. Oakland: Univ. Calif. Div. Ag. and Nat. Res. Publ. 21560 (poster).

The best storage environment for an individual fruit or vegetable depends on its unique requirements for temperature, relative humidity, and ethylene exposure. Most compatibility charts for mixing products during postharvest handling divide fruits and vegetables into eight groups. In practice it is very difficult to separate products into this many groups-very few wholesale or retail handling facilities, if any, have eight temperature-controlled rooms.

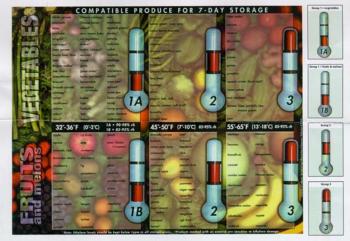

We have developed a Three-Group Chart that is easier to use and still provides good product life information (click image at left for larger view of the poster; actual size in 22 x 28inches). This publication includes poster and thermometer diagrams. For additonal information, see item description (pdf); for purchase, see our Order Form (pdf).

- Group 1: 32o to 36oF (0o to 2oC), 90% to 98% relative humidity contains the majority of produce in North American food-handling operations, including most leafy vegetables, Cole crops, and temperate-origin fruits and berries.

- Group 2: 45o to 50oF (7o to 10oC), 85% to 95% relative humidity contains citrus and subtropical fruits and many fruit-type vegetables.

- Group 3: 55o to 65oF (13o to 18oC) ), 85% to 95% relative humidity contains common root-type vegetables, winter (hard-rind) squashes, and most tropical fruits and melons.

In grouping products that are potentially incompatible, we assumed (1) that storage is for 7 days or less and (2) that ethylene concentrations are kept below l ppm. The 7-day storage time allows us to recommend storage temperatures for some chilling-sensitive products that are colder than long-term storage. For example, we put citrus fruits in Group 2 (45 to 50oF). Although many citrus fruits can be damaged by long-term storage in this range, 7 days' storage in this rarely causes chilling injury. This temperature has the added advantage of slowing the growth of decay-causing fungi, as compared to warmer-temperature storage.

Ethylene must be kept below l ppm for all groups, particularly Group l, which contains most of the very sensitive green vegetables. Ethylene can be kept low in cold storage by (l) separating storage rooms from ethylene sources such as ripening rooms; (2) ventilating with outside air; (3) eliminating the use of propane equipment in storage areas; and (4) using an ethylene scrubber. Ethylene levels in refrigerated highway trailers appear to be fairly low, probably because of high air-infiltration rates. A limited number of surveys indicate that ethylene is below l ppm in these vehicles. However, ethylene levels may be damaging when ethylene-sensitive products are shipped with ethylene producers in new vehicles, which tend to be tightly sealed.

Group l requires a higher humidity because it contains many leafy vegetables, which lose water quickly and wilt easily. The two higher-temperature groups require a lower humidity because these products lose water more slowly than green vegetables, and lower humidity helps maintain fiberboard box strength.

Following these recommendations will not necessarily eliminate all damage caused by less-than-optimum temperature, relative humidity, or ethylene exposure. Damage from these causes is the sum of all abuses after harvest. For example, moisture loss starts at harvest and can amount to several percent before the product leaves the cooler at the farm. The product may look fine until the last small loss of moisture at wholesale storage. The solution for the problem may not be simply increasing humidity al wholesale storage-moisture loss in transport, cooling, and before packaging should also be reduced.

At retail stores, which rarely have three temperature-controlled rooms, Group 3 products can be held in an air-conditioned corridor or preparation room. At wholesale distribution facilities, which may have more than three storage rooms, two rooms can be designated Group 1, one for vegetables (Group 1A) and one for fruits [and melons] (Group 1B). This separates the ethylene-sensitive vegetables from the fruits, some of which produce ethylene. The Group l fruit room could also be kept at the lower humidity range (85% to 95%) recommended for the Group 2 and 3 rooms. The Group 3 room can also be used for ripening products such as pears and stone fruits.

We have developed a simple coding system that designates the three storage groups. Each box of produce should have the appropriate code printed on both box ends, allowing warehouse personnel to easily determine in which room to store the product. The poster is accompanied by four temperature codes, which are printed on separate sheets to be placed on cold room doors.