Product Description

Maturity and Quality

Soluble solids/acid ratio of 8 or higher and yellow-orange color at least on 25% of the fruit surface or soluble solids/acid ratio of 10 or higher and green-yellow color on 25% or greater of the fruit surface.

- Color intensity and uniformity

- Firmness

- Size

- Shape

- Smoothness

- Freedom from decay

- Freedom from defects including physical damage (abrasions and bruising), skin blemishes and discoloration, freezing damage, chilling injury, and insect damage

- Flavor quality is related to soluble solids/acid ratio and absence of off-flavor-causing compounds including fermentative metabolites

Postharvest Handling and Storage

3-8°C (38-46°F) for up to 3 months, depending on cultivar, maturity-ripeness stage at harvest and production area. Some Florida-grown cultivars can be kept at 0-1°C (32-34°F). Arizona-grown Valencia oranges should be kept at 9°C (48°F).

| Temperature | 5°C (41°F) | 10°C (50°F) | 15°C (59°F) | 20°C (68°F) |

|---|---|---|---|---|

| ml CO2/kg·hr | 2-4 | 3-5 | 6-12 | 11-17 |

To calculate heat production multiply ml CO2/kg·hr by 440 to get Btu/ton/day or by 122 to get kcal/metric ton/day.

Exposure to 1-10ppm ethylene for 1-3 days at 20-30°C (68-86°F) may be used for degreening oranges. This treatment does not influence the internal quality (including soluble solids/acid ratio) and may accelerate deterioration and decay incidence.

90-95%

< 0.1 µl/kg·hr at 20°C (68°F)

A combination of 5-10% O2 and 0-5% CO2 can be useful for delaying senescence and for firmness retention but does not have a significant effect on decay incidence and severity, which is the limiting factor to long-term storage of oranges. Fungistatic levels (10-15%) of CO2 are not used because they may result in off-flavors due to accumulation of fermentative metabolites. Commercial use of CA on oranges during storage and transport is very limited.

Temperature & Controlled Atmosphere Photos

Title: Chilling Injury Photo Credit: Don Edwards, UC Davis |

Title: Freezing Damage Photo Credit: Jim Thompson, UC Davis |

Disorders

Chilling injury. Symptoms include pitting, brown staining, and increased decay incidence. Minimum safe temperature depends on cultivar, production area, and maturity-ripeness stage at harvest. Severity of symptoms can be reduced if water loss is minimized (by waxing or film wrapping) and if decay-causing fungi are controlled (by use of fungicides and/or biological antagonists).

Stem-end rind breakdown. Symptoms include shriveling and peel injury around the stem due to aging.

Rind staining. This disorder results from overmaturity at harvest. It can be reduced by preharvest application of gibberellic acid that delays senescence.

Oil spotting (Oleocellosis). Harvesting and handling turgid oranges can result in release of oil that damages surrounding tissues. Thus, oranges should not be harvested when fully turgid such as early in the morning and soon after rain or irrigation.

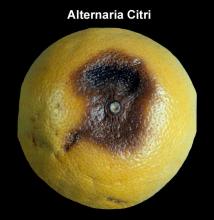

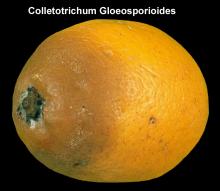

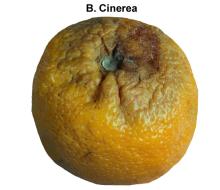

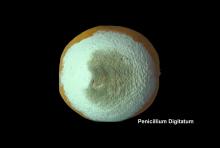

Important Diseases:

- Green mold (Penicillium digitatum)

- Blue mold (Penicillium italicum)

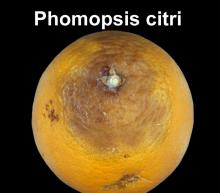

- Phomopsis stem-end rot (Phomopsis citri)

- Stem end rot (Lasiodiplodia theobromae)

- Brown rot (Phytophthora citrophthora)

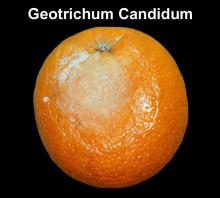

- Sour rot (Geotrichum candidum)

Control Strategies

- Minimizing physical damage during harvesting and handling

- Treatment with postharvest fungicides and/or biological antagonists. Also, heat treatments may be used

- Prompt cooling and subsequent maintenance of optimum temperature and relative humidity throughout marketing operations

- Removal and/or exclusion of ethylene

- Effective sanitation procedures throughout postharvest handling