Product Description

Maturity and Quality

Based on berry surface color. US: minimum 1/2 or 3/4 berry surface showing red or pink color, depending on grade. Calif.: minimum 2/3 berry surface showing red or pink color.

- Appearance (color, size, shape, freedom from defects)

- Firmness

- Flavor (soluble solids, titratable acidity and flavor volatiles)

- Nutritional value (Vitamin C)

- For acceptable flavor, a minimum of 7% soluble solids and/or a maximum of 0.8% titratable acidity are recommended

Postharvest Handling and Storage

0 ± 0.5°C (32 ± 1°F)

| Temperature | 0°C (32°F) | 10°C (50°F) | 20°C (68°F) |

| ml CO2/kg·hr | 6-10 | 25-50 | 50-100 |

To calculate heat production, multiply ml CO2/kg·hr by 440 to get BTU/ton/ day or by 122 to get kcal/metric ton/day.

Strawberries do not respond to ethylene by stimulation of ripening processes (strawberries should be harvested near to full ripe). Removal of ethylene from storage air may reduce disease development.

90 to 95%

2H4/kg·hr at 20°C (68°F)

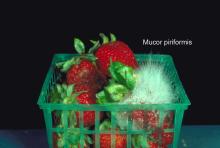

Modified atmosphere packaging for shipment with 10 to 15% carbon dioxide reduces the growth of Botrytis cinerea (Grey Mold Rot) and reduces the respiration rate of the strawberries thereby extending postharvest life. Use of whole pallet covers for modified atmospheres is the most common method.

Temperature & Controlled Atmosphere Photos

Title: Temperature Effects

Photo Credit: Don Edwards, UC Davis

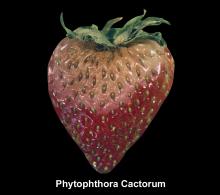

Disorders

Perhaps because of rapid marketing and very short storage periods, physiological disorders are not a major concern with strawberry fruit.

Diseases are the greatest cause of postharvest losses in strawberries. Postharvest fungicides are not used on strawberries; therefore, prompt cooling, storage at 0°C (32°F), preventing fruit injury, and shipment under high carbon dioxide are the best methods for disease control. In addition, care should be taken to keep diseased or wounded berries out of trays at harvest as strawberry diseases will spread from diseased to nearby healthy berries (nesting).

Irradiation has been tested on strawberries for decay control with mixed success. Doses needed for adequate decay control without high carbon dioxide generally result in excessive berry softening.

Botrytis Rot (Grey Mold). Caused by Botrytis cinerea is the greatest cause of postharvest strawberry losses. This fungus continues to grow even at 0°C (32°F), however growth is very slow at this temperature.

Rhizopus Rot. Caused by the fungus Rhizopus stolonifer. Spores of this fungus are usually present in the air and are easily spread. This fungus will not grow at temperatures below 5°C (41°F), therefore temperature management is the simplest method of control.

Figure 1. Cooling and deterioration. Strawberries should be cooled as soon as possible after harvest; delays beyond 1 hour reduce the percentage of marketable fruit.

References

References from scientifically validated sources will be added in the future.