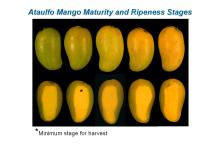

Maturity and Quality

- Change in fruit shape (fullness of the cheeks)

- Change in skin color from dark-green to light-green to yellow (in some cultivars). Red color on the skin of some cultivars is not a dependable maturity index

- Change in flesh color from greenish-yellow to yellow to orange

- Uniformity of shape and size; skin color (depending on cultivar); flesh firmness

- Freedom from decay and defects, including sunburn, sapburn, skin abrasions, stem-end cavity, hot water scald, chilling injury, and insect damage

- Changes associated with ripening include starch to sugar conversion (increased sweetness), decreased acidity and increased carotenoids and aroma volatiles

- There are large differences in flavor quality (sweetness, sourness, aroma) and textural quality (fiber content) among cultivars

Postharvest Handling and Storage

13°C (55°F) for mature-green mangoes

10°C (50°F) for partially-ripe and ripe mangoes

| Temperature | 10°C (50°F) | 13°C (55°F) | 15°C (59°F) | 20°C (68°F) |

|---|---|---|---|---|

| ml CO2/kg·hr | 12-16 | 15-22 | 19-28 | 35-80 |

To calculate heat production multiply ml CO2/kg·hr by 440 to get Btu/ton/day or by 122 to get kcal/metric ton/day.

Exposure to 100 ppm ethylene for 12 to 24 hours at 20 to 22°C (68 to 72°F) and 90-95% relative humidity results in accelerated and more uniform ripening of mangoes within 5-9 days, depending on cultivar and maturity stage. Carbon dioxide concentration should be kept below 1% in the ripening room.

90-95%

| Temperature | 10°C (50°F) | 13°C (55°F) | 15°C (59°F) | 20°C (68°F) |

|---|---|---|---|---|

| ul C2H4/kg·hr | 0.1-0.5 | 0.2-1.0 | 0.3-4.0 | 0.5-8.0 |

- Optimum CA: 3-5% O2 and 5-8% CO2

- CA delays ripening and reduces respiration and ethylene production rates

- Postharvest life potential at 13°C (55°F): 2-4 weeks in air and 3-6 weeks in CA, depending on cultivar and maturity stage

- Exposure to below 2% O2 and/or above 8% CO2 may induce skin discoloration, grayish flesh color, and off-flavor development

Disorders

Sapburn. Dark-brown to black discoloration of mango skin due to chemical & Physiological injury from exudate (sap) from cut stem.

Skin abrasions. Abrasions due to fruit rubbing against rough surfaces or each other result in skin discoloration and accelerated water loss.

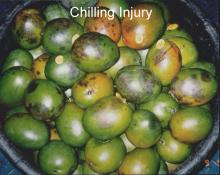

Chilling injury. Symptoms include uneven ripening, poor color and flavor, surface pitting, grayish scald-like skin discoloration, increased susceptibility to decay, and, in severe cases, flesh browning. Chilling injury incidence and severity depend on cultivar, ripeness stage (riper mangoes are less susceptible) and temperature and duration of exposure.

Heat injury. Exposure to temperatures above 30°C (86°F) for longer than 10 days results in uneven ripening, mottled skin and strong flavor. Exceeding the time and/or temperature combinations recommended for decay and/or insect control, such as 46.4°C (115.5°F) water dip for 65-90 minutes (depending on fruit size) causes heat injury (skin scald, blotchy coloration, uneven ripening).

Internal flesh breakdown (stem-end cavity). Flesh breakdown and development of internal cavities between seed and peduncle. This disorder is more prevalent in tree-ripened mangoes.

Jelly-seed (premature ripening). Disintegration of flesh around seed into a jelly-like mass.

Soft-nose. Softening of tissue at apex. Flesh appears over-ripe and may discolor and become spongy. This disorder may be related to calcium deficiency.

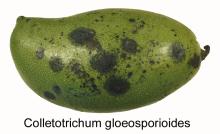

Anthracnose. Caused by Colletotrichum gloesporioides, begins as latent Disorders infections in unripe fruit and develops when the mangoes begin to ripen. Lesions may remain limited to the skin or may invade and darken the flesh.

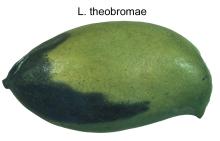

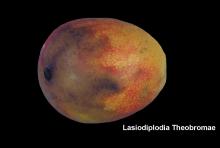

Diplodia stem-end rot. Caused by Lasiodiplodia theobromae, affects mechanically-injured areas on the stem or skin. The fungus grows from the pedicel into a circular black lesion around the pedicel.

Control Strategies

- Careful handling to minimize mechanical injuries

- Hot water treatment: 5-10 minutes (depending on fruit size) dip in 50°C ± 2°C (122°F ± 4°F) water

- Postharvest fungicide (imazalil or thiabendazole) treatment alone or in combination with hot water treatment

- Maintaining optimum temperature and relative humidity during all handling steps

[For more information, see our publication “Fruit Ripening and Ethylene Management”, available for purchase using our Publication order form.]