Product Description

Last updated on April 2025.

Maturity and Quality

True leaves typically reach about 10-15 cm (3.9-5.9 in) long, and with the petiole or stalk, leaves can reach up to 20 to 70 cm (7.8 to 27.6 in) long at harvest.

Basal leaves, or broadly obovate, are 20-30 cm (7.8-11.8 in) long, firm, dark green, and glossy. The base narrows into a broad stalk, and the whole margin may have inconspicuous rounded or undulated teeth.

Visual Appearance: Leaves should remain intact without mechanical damage, disease spots, or insect infestations. Leaves must be free of yellowing, wilting, or blemishes.

Color: Leaves should display a uniform dark green color, while petioles should be pale green or white.

Freshness: Leaves should appear glossy and firm and retain adequate moisture to ensure a crisp texture.

Figure 1. Freshly harvested Pakchoi at three different maturity stages: immature, mature, and overmature. Photo Credit: Postharvest Team, Jiangsu Academy of Agricultural Sciences (JAAS), China.

Postharvest Handling and Storage

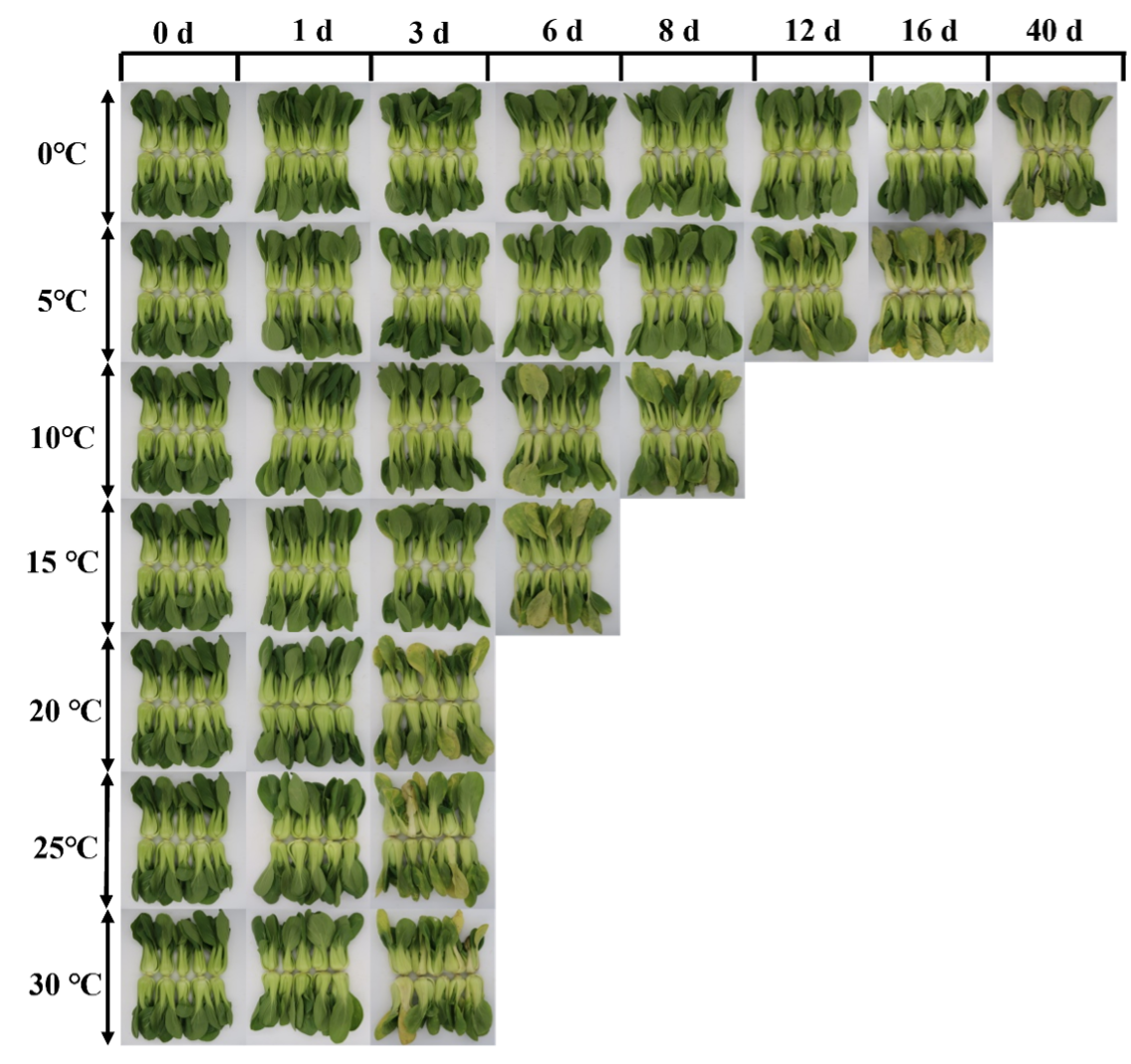

Pakchoi stored at 0°C (32°F) can maintain freshness for up to 40 days. Increasing the temperature accelerates leaf yellowing, water loss, aging, and decay. However, storing at 0°C (32°F) poses a high risk of freezing, thus the recommended storage temperature is 2°C (36°F). When stored at 15°C (59°F), the shelf life of pakchoi is reduced to less than 7 days, and at temperatures above 15°C (59°F), it drops to less than 4 days.

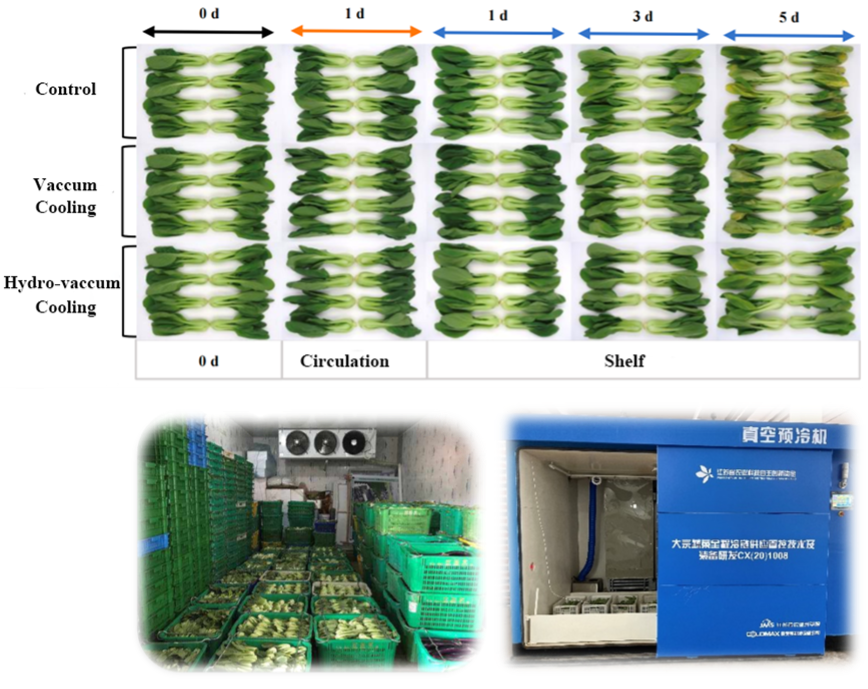

Rapid postharvest initial cooling is crucial for preserving the quality of pakchoi. Forced air, vacuum, and hydro-vacuum are effective initial cooling methods, and hydro-vacuum cooling is particularly recommended.

Figure 2. Shelf life of Pakchoi under varying storage temperatures. This image highlights the impact of temperature on the shelf life of Pakchoi. Photo Credit: Postharvest Team, Jiangsu Academy of Agricultural Sciences (JAAS), China.

25°C (77°F): 15 to 50 mg CO2/(kg·h); 0°C (32°F): 0.5 to 2 mg CO2/(kg·h)

The respiration rate may vary as it is closely related to the season and harvest timing. Generally, pakchoi harvested in the summer exhibits a higher respiration rate than in the winter.

Although the ethylene production rate in pakchoi is relatively low, it's sensitive to ethylene. Exposure to 5 ppm ethylene can accelerate leaf yellowing and promote disease development.

>95%

Ethylene production rates are generally low, only 2-5 μL/(kg·h) at 25°C (77°F).

Pakchoi is not commonly stored under controlled atmosphere (CA) conditions for retail. However, if extended preservation beyond 40 days is required—such as for long-distance maritime transport—CA storage or other preservation methods like controlled freezing-point preservation or individual quick freezing can be among the most effective strategies for maintaining freshness. At optimal storage temperatures, a CA containing 2% oxygen and 2-5% carbon dioxide can help preserve pakchoi's color and overall quality.

Disorders

Freezing Injury. Pakchoi freezes at about -0.2°C (31.64°F). The most common symptom of freezing injury is a water-soaked appearance of the stalks and leaves, followed by rapid decay due to bacterial soft rot.

Figure 3. Frost-damaged packchoi. Water-soaked regions caused by freezing injury are indicated with red arrows. Photo Credit: Postharvest Team, Jiangsu Academy of Agricultural Sciences (JAAS), China.

Physical Injury. Due to its delicate tissues and harvesting methods involving cutting, pakchoi is prone to physical injuries during harvest. Such injuries increase the risk of decay.

Leaf yellowing. Chlorophyll degradation leads to diffuse yellowing of the leaves, a primary issue affecting pakchoi quality during postharvest storage and transportation.

Figure 4. Pakchoi exhibiting leaf yellowing. Leaf yellowing is a common sign of senescence and quality deterioration during storage. Photo Credit: Postharvest Team, Jiangsu Academy of Agricultural Sciences (JAAS), China.

Bacterial Soft-Rot (Pectobacterium carotovorum) usually begins at the base of the leaves and can also infect the leaves, causing tissue softening, water-soaked regions, and emission of foul odor.

Figure 5. Bacterial soft rot in pakchoi. This image highlights symptoms of bacterial infection, including a dark water-soaked region. Photo Credit: Postharvest Team, Jiangsu Academy of Agricultural Sciences (JAAS), China.

Fusarium wilt (Fusarium spp.) primarily infects older leaves, causing the affected areas to turn yellow and develop black spots. This pathogen is mainly soil-born and can cause infection during postharvest storage.

Figure 6. Fusarium wilt in pakchoi. Characteristic symptoms include discoloration and wilting. PPhoto Credit: Postharvest Team, Jiangsu Academy of Agricultural Sciences (JAAS), China.

Special Considerations

Hydro-vacuum cooling

Hydro-vacuum cooling to a final temperature of 4 oC (39.2°F), final pressure of 0.9 kPa, and watering rate of 5% (weight of the product) can effectively mitigate quality loss and accelerate the initial cooling process, thereby delaying senescence in pakchoi.

Figure 7. Comparison of Pakchoi quality and shelf life under different postharvest treatments: control, vacuum cooling, and hydro-vacuum cooling. The image also features internal and external scenes of the cooling process in operation. Photo Credit: Postharvest Team, Jiangsu Academy of Agricultural Sciences (JAAS), China.

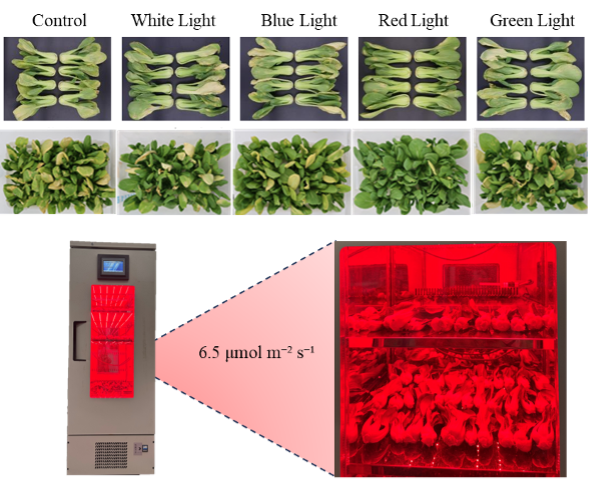

Red LED irradiation

Red LED irradiation at 6.5 μmol/(m²·s) from 9:00 AM to 9:00 PM, which has been experimentally explored to simulate retailer shelf lighting exposure time under laboratory conditions, can delay the yellowing of postharvest pak choi, maintaining its quality and extending its shelf life.

Figure 8. Phenotypic response of pakchoi to red light irradiation. Performed under controlled conditions in a lighting-preservation chamber, demonstrating the effect of light treatment on postharvest quality. Photo Credit: Agricultural Products Preservation Technology and Equipment Innovation Team, JAAS.

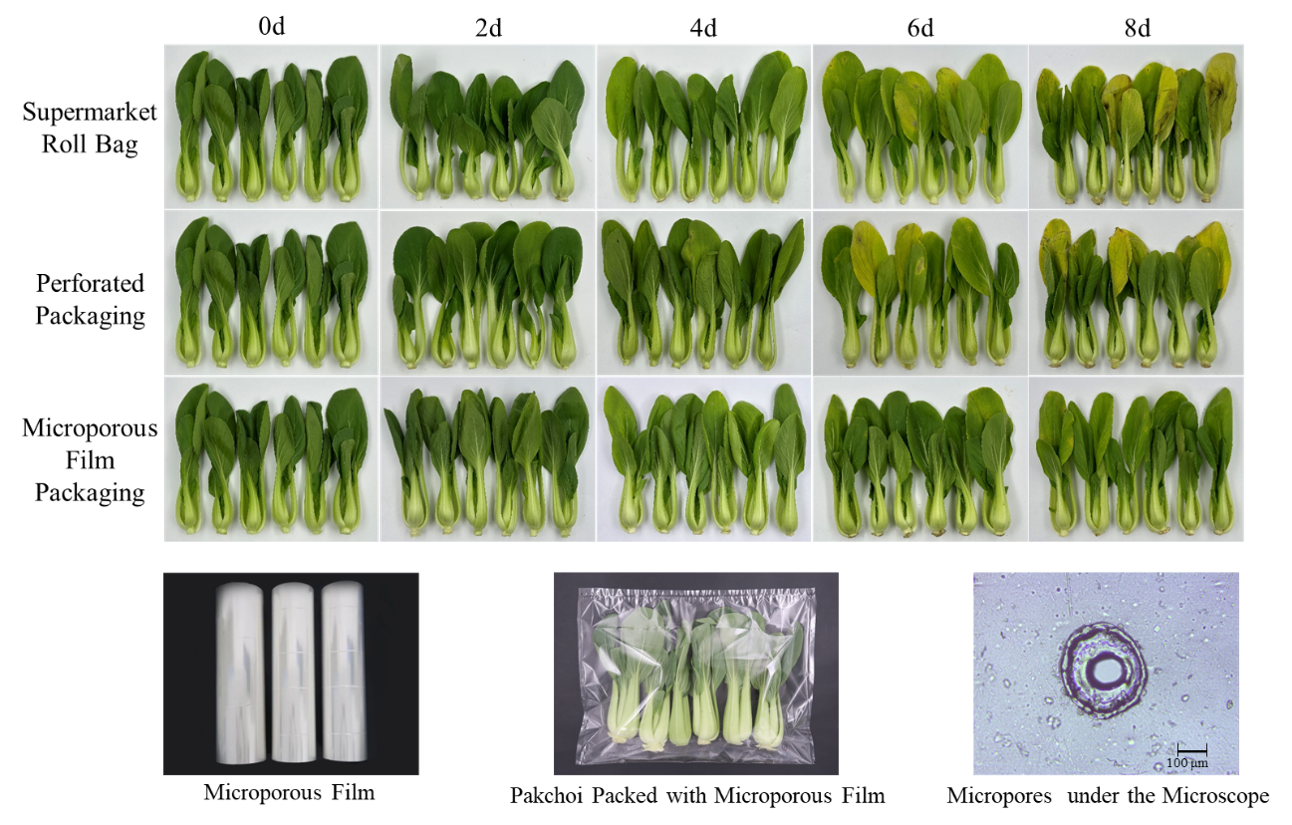

Microporous Film Packaging

Microporous film (Water Vapor Transmission Rate, WVTR: 5.0245 g/m2·d; Oxygen Transmission Rate, OTR: 3.355E-3cm3/m2·d·Pa; Carbon Dioxide Transmission Rate, CO2TR: 1.063E-3cm3/m2·d·Pa; Micropore Spacing: 2 cm; Micropore Diameter: 100 μm) packaging can help maintain an appropriate atmospheric composition within the packaging, effectively delaying senescence in pakchoi. At 15℃ (59°F), the pakchoi packed in microporous film can retain its quality, particularly reducing color loss, for up to 8 days.

Figure 9. Comparison of Pakchoi packaged using supermarket bags, perforated film, and microporous film. This image highlights the differences in the quality and shelf life of Pakchoi, attributed to the use of different packaging materials. The image also portrays the microstructure and appearance of the microporous film packaging material. Photo Credit: Postharvest Team, Jiangsu Academy of Agricultural Sciences (JAAS), China.