Maturity and Quality

Change of skin color from dark-green to light-green with some yellow at the blossom end (color break). Papayas are usually harvested at color break to ¼ yellow for export or at ½ to ¾ yellow for local markets.

Flesh color changes from green to yellow or red (depending on cultivar) as the papayas ripen.

A minimum soluble solids of 11.5% is required by the Hawaiian grade standards.

- Papayas picked ¼ to full yellow taste better than those picked mature - green to ¼ yellow because they do not increase in sweetness after harvest

- Uniformity of size and color; firmness; freedom from defects such as sunburn, skin abrasions, pitting, insect injury, and blotchy coloration; freedom from decay

Postharvest Handling and Storage

13°C (55°F) for mature-green to ¼ yellow papayas

10°C (50°F) for partially-ripe (¼ to ½ yellow) papayas

7°C (45°F) for ripe (>½ yellow) papayas

| Temperature | 7°C (45°F) | 10°C (50°F) | 13°C (55°F) | 15°C (59°F) |

|---|---|---|---|---|

| ml CO2/kg·hr | 3-5 | 4-6 | 10-12 | 15-35 |

To calculate heat production multiply ml CO2/kg·hr by 440 to get Btu/ton/day or by 122 to get kcal/metric ton/day.

Exposure to 100 ppm ethylene at 20 to 25°C (68 to 77°F) and 90-95% relative humidity for 24-48 hours results in faster and more uniform ripening (skin yellowing and flesh softening, but little or no improvement in flavor) of papayas picked at color break to ¼ yellow stage.

90-95%

| Temperature | 7°C (45°F) | 10°C (50°F) | 13°C (55°F) | 15°C (59°F) |

| µl C2H4/kg·hr | 0.1-2 | 0.2-4 | 0.5-8 | 1-15 |

- Optimum CA: 3-5% O2 and 5-8% CO2

- Benefits of CA include delayed ripening and firmness retention

- Postharvest life potential at 13°C (55°F): 2-4 weeks in air and 3-5 weeks in CA, depending on cultivar and ripeness stage at harvest

- Exposure to O2> levels below 2% and/or CO2 levels above 8% should be avoided because of the potential for development of off-flavors and uneven ripening

Disorders

Skin abrasions. Result in blotchy coloration such as green islands (areas of skin that remain green and sunken when the fruit is fully-ripe) and accelerate water loss. Abrasion and puncture injuries are more important than impact injury for papayas.

Chilling injury. Symptoms include pitting, blotchy coloration, uneven ripening, skin scald, hard core (hard areas in the flesh around the vascular bundles), water soaking of tissues, and increased susceptibility to decay. Increased alternaria rot was observed in mature-green papayas kept for 4 days at 2°C, 6 days at 5°C, 10 days at 7.5°C, or 14 days at 10°C. Susceptibility to chilling injury varies among cultivars and is greater in mature- green than ripe papayas (10 vs. 17 days at 2°C; 20 vs. 26 days at 7.5°C).

Heat injury. Exposure of papayas to temperatures above 30°C (86°F) for longer than 10 days or to temperature-time combinations beyond those needed for decay and/or insect control result in heat injury (uneven ripening, blotchy ripening, poor color, abnormal softening, surface pitting, accelerated decay). Quick cooling to 13°C (55°F) after heat treatments minimizes heat injury.

Anthracnose. Caused by Colletotrichum gloesporioides, is a major cause of postharvest losses. Latent infections of unripe papayas develop as the fruits ripen. Lesions appear as small, brown, superficial, watersoaked lesions that may enlarge to 2.5 cm (1 inch) or more in diameter.

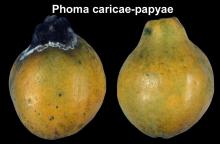

Black stem-end rot. Caused by Phoma caricae-papayae attacks fruit pedicel. After harvest, the disease lesion on fruits appear in the stem area which becomes dark-brown to black. Another stem-end rot is caused by Lasiodiplodia theobromae.

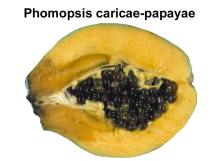

Phomopsis rot. Caused by Phomopsis caricae-papayae begins in the stem end or a fruit skin wound and can develop rapidly in ripe fruits; invaded tissue softens and darkens slightly.

Phytophthora stem-end rot. Caused by Phytophthora nicotianae var. parasitica begins as water-soaked areas followed by white mycelium that become encrusted.

Alternaria rot. Caused by Alternaria alternata follows chilling injury of papayas kept at temperatures below 12°C (54°F).

Heat Treatments for Insect Control

- Hot water treatment: 30 minutes at 42°C (107.6°F) followed within 3 minutes by a 49°C (120.2°F) dip for 20 minutes

- Vapor heat treatment: Fruit temperature is raised by saturated water vapor at 44.4°C (112°F) until the center of the fruit reaches that temperature, and then held for 8.5 hours

- Forced hot air treatment: 2 hours at 43°C (109.4°F) + 2 hours at 45°C (113°F) + 2 hours at 46.5°C (115.7°F) + 2 hours at 49°C (120.2°F)

Control Strategies

- Careful handling to minimize mechanical injuries

- Prompt cooling and maintenance of optimum temperature and relative humidity throughout postharvest handling operations

- Application of fungicides, such as thiabendazole (TBZ)

- Dipping in hot water at 49°C (120°F) for 20 minutes