Maturity and Quality

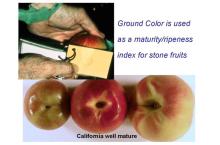

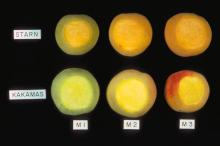

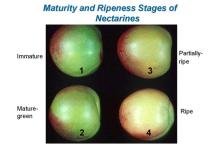

In California, harvest date is determined by skin ground color changes from green to yellow in most cultivars. A color chip guide is used to determine maturity of each cultivar.

A three tier maturity system is used in California:

- US-Mature (Minimum Maturity)

- Well-Mature

- Tree Ripe

Measurement of fruit firmness is recommended in cultivars where skin ground color is masked by full red color development before maturation. Maximum maturity: The flesh firmness at which fruits can be handled without bruising damage is measured with a penetrometer with an 8 mm- (5/16") tip. Bruising susceptibility varies among cultivars.

- High consumer acceptance is attained on fruit with high soluble solids content (SSC)

- Fruit acidity, SSC/acidity ratio, and phenolic content are also important factors in consumer acceptance

- There is no established minimum quality standard for peaches and nectarines

- Fruit with 2-3 pounds-force flesh firmness is considered "ready to eat"

- Fruit below 6-8 pounds-force measured on the cheek are more acceptable to the consumer

Postharvest Handling and Storage

-1 to 0°C (30.5-32°F)

Freezing point varies depending on SSC from -3 to -2.5°C (26.5 to 29.5°F)

| Temperature | 0°C (32°F) | 10°C (50°F) | 20°C (68°F) |

|---|---|---|---|

| ml CO2/kg·hr | 2-3 | 8-12 | 32-55 |

To calculate heat production multiply ml CO2/kg·hr by 440 to get Btu/ton/ day or by 122 to get kcal/metric ton/day.

In general peaches and nectarines harvested at Well Mature (higher than US-Mature) will ripen properly without exogenous ethylene application. Ethylene application to fruit harvested at the US-Mature maturity will only ripen the fruit more uniformly without speeding up the rate of ripening. A few cultivars may need to be exposed to ethylene to ripen properly.

90-95% R.H.; an air velocity of approximately 50 CFM is suggested during storage.

- < 0.01-5 µl/kg·hr (range)* at 0°C (32°F)

- 0.02-10 µl/kg·hr at 5°C (41°F)

- 0.05-50 µl/kg·hr at 10°C (50°F)

- 0.1-160 µl/kg·hr at 20°C (68°F)

*The lower end of this range is for mature but unripe fruit; higher values are for ripe fruit.

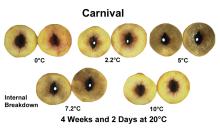

The major benefits of CA during storage/shipment are retention of fruit firmness and ground color. Decay incidence has not been reduced by using CA 1-2% O2 + 3-5 % CO2. CA conditions of 6% O2 + 17% CO2 are suggested for reduction of internal breakdown during shipments, but the efficacy is related to cultivar, preharvest factors, market life and shipping time period.

Effects of Genotype and Cultural Practices on Postharvest Life

There are approximately 350 peach and nectarine cultivars in California. Market life varies among them and it is strongly affected by temperature management. Maximum market life is obtained when fruit is stored at approximately 0°C (32°F). Maximum market life varies from 1-7 weeks for nectarine cultivars and from 1-5 weeks for peach cultivars. Because internal breakdown is the main limitation to market life, minimum postharvest life occurs when fruit is stored at 5°C (41°F). Cultural practices have an important role in determining fruit quality and storage potential. Leaf nitrogen content between 2.6-3.0% is advised to obtain high red color development and maximum storage performance. Small size fruit grown in the outside canopy position have a longer market life than large size fruit grown in the inside position.

Disorders

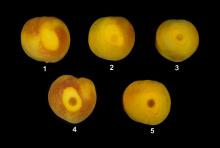

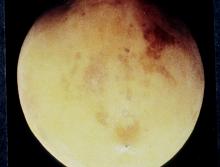

Internal Breakdown or Chilling Injury. This physiological problem is characterized by flesh internal browning, flesh mealiness, flesh bleeding, failure to ripen and flavor loss. These symptoms develop during ripening after a cold storage period, thus, are usually detected by consumers. Fruit stored within the 2.2-7.6°C (36-46°F) temperature range are more susceptible to this disorder.

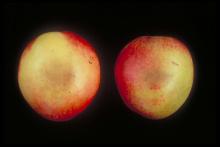

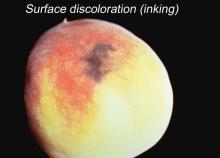

Inking (Black Staining). It is a comestic problem affecting only the skin of peaches and nectarines. It is characterized by black or brown spots or stripes. These symptoms appear generally 24-48 hours after harvest. Inking occurs as a result of abrasion damage in combination with heavy metals (iron, copper and aluminum) contamination. This occurs usually during the harvesting and hauling operations, although it may occur in other steps during postharvest handling. Gentle fruit handling, short hauling, avoiding any foliar nutrient sprays within 15 days before harvest, and following the suggested preharvest fungicide spray interval guidelines are our recommendations to reduce inking in California.

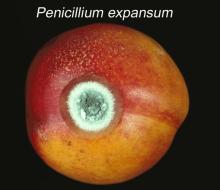

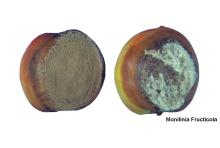

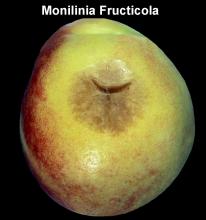

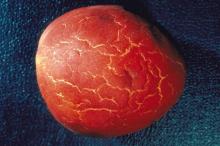

Brown Rot. Caused by Monilia fructicola is the most important postharvest disease of stone fruits. Infection begins during flowering and fruit rot may occur before harvest but often occurs postharvest. Orchard sanitation to minimize infection sources, preharvest fungicide application, and prompt cooling after harvest are among the control strategies. Also, postharvest fungicide treatment may be used.

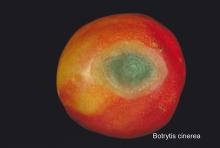

Gray Mold. Caused by Boyrytis cinerea can be serious during wet spring weather. It can occur during storage if the fruit has been contaminated through harvest and handling wounds. Avoiding mechanical injuries and good temperature management are effective control measures.

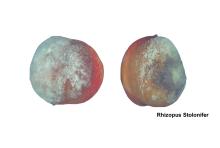

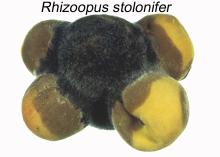

Rhizopus Rot. Caused by Rhizopus stolonifer can occur in ripe or near ripe stone fruits kept at 20 to 25°C (68 to 77°F). Cooling the fruits and keeping them below 5°C (41°F) is very effective against this fungus.

[For more information, see our publications “Fruit Ripening and Ethylene Management”, and “Peaches, Plums, and Nectarines-Growing and Handling for Fresh Market”, available for purchase using our Publication order form.]