Maturity and Quality

Sweet potatoes are harvested when roots have reached the desirable size. Irrigation is typically stopped 2 to 3 weeks before harvest so that vines begin drying before they are removed and roots are harvested.

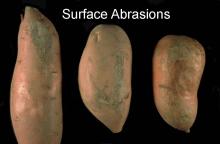

Good quality sweet potatoes should be smooth and firm, with uniform shape and size, be free from mechanical damage, and have a uniform peel color typical of the variety.

There are four U.S. Grades for sweet potato (U.S. Extra No. 1, U.S. No.1, U.S. commercial and U.S. No. 2), and grades are based on degree of freedom from defects (dirt, roots, cuts, bruises, growth cracks, decay, insects, and diseases), but also size and weight categories.

Postharvest Handling and Storage

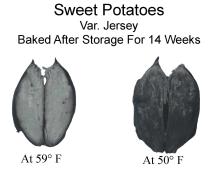

The recommended conditions for commercial storage are to keep roots cool and dry. Sweet potato roots are chilling sensitive and should be stored between 12.5°C and 15°C (55°F to 59°F) with high relative humidity (>90%). A storage life of 6-10 months can be expected under these conditions, although sprouting may begin to occur after about 6 months depending on cultivar. Temperatures above 15°C (59°F) lead to more rapid sprouting and weight loss. Careful handling during harvesting will minimize mechanical damage to the skin and reduce decay incidence during storage. Roots are not washed before storing in bins or crates, but only after removal for selection and packing for marketing. Sweet potato roots are commonly stored in evaporatively cooled rooms, supplemented by mechanical refrigeration late in the storage period when warm ambient temperatures occur.

| Temperature | 10°C (50°F) | 15°C (59°F) | 25°C (77°F) |

| ml CO2/kg·hr | |||

| Cured | 7 | 10 - 12 | --- |

| Noncured | --- | 15 | 27 - 35 |

To calculate heat production multiply mL CO2/kg·hr by 440 to get Btu/ton/day or by 122 to get kcal/metric ton/day.

>95% for long-term storage; 70-90% for short-term handling for marketing

Sweet potato roots produce very low amounts of ethylene (~0.1 µL/kg·hr), although much higher rates can occur after chilling, wounding and decay development. Exposure to ethylene (1 to 10 ppm) increases respiration rates and phenolic metabolism and adversely affects flavor and color of cooked roots.

There is no commercial use of controlled atmospheres for sweet potato storage. Respiration rates of roots are reduced as oxygen is lowered from 21 to 3%. Oxygen concentrations below 3% may results in increased respiration rates due to fermentative metabolism. Response of roots to increased carbon dioxide levels is not known.

Disorders

Chilling injury. Sweet potato roots are very sensitive to chilling injury at temperatures of 12.5°C (55°F) or below. Symptoms of chilling injury include fungal decay, internal pulp browning, and root shriveling. Chilled roots that have been cooked can have "hardcore" defect and a darker color than non-chilled roots.

Chilling and mechanical injury predispose sweet potatoes to decay, especially Rhizopus soft rot. Postharvest fungicides may be applied to reduce the risk of Rhizopus after handling for marketing. There are numerous other decay-causing fungi including black rot (Ceratocystis) and Fusarium rot. Seed piece treatment and postharvest curing are the main control measures for these organisms. In warm wet production conditions, bacterial rots can also cause postharvest losses.

Special Considerations

Curing. The periderm of sweetpotato roots is easily damaged during harvest and handling, and this leads to an unsightly appearance, high rates of water loss, and increased susceptibility to decay. The process of curing the damaged skin or "wound healing" can be achieved by holding roots at 25-32°C (77-90°F) under high relative humidity (>90 to 100%) for several days to 1 week. The conditions for curing sweetpotatoes are similar to those used for other tropical root and tuber crops. Growers often load bins of warm roots into storage rooms and do not turn on the fans for evaporative cooling until after about 1 week. This interval before cooling provides the warm humid conditions necessary for curing wounds.