Product Description

Maturity and Quality

Harvesting at the optimal maturity is critical for maintaining pistachio quality and avoiding losses. The following indices help determine the ideal harvest time:

Ease of hull separation from the shell

Hull color: cream color with or without pink sections indicates maturity

Shell dehiscence (splitting)

Decrease in fruit removal force

Kernel dry weight and crude fat content increase; moisture content decreases

Maturation within the tree occurs unevenly. As a result, the ideal harvest time is when 70–80% of the fruits meet the desired maturity criteria [1,2].

Key quality factors for pistachios include:

Appearance: Cleanliness, nut size relative to kernel size (percent edible portion), and absence of defects like shell staining, insect damage, mold, kernel discoloration, and shriveling.

Texture: Crispness, chewiness, and other textural attributes influenced by the degree and uniformity of dryness.

Safety: Aflatoxin contamination must be avoided by protecting the nuts from Aspergillus growth before and after harvest, and during drying.

Freedom from Foreign Material: Pistachios should be free from loose kernels, shell pieces, dust, blanks, non-split shells, and adhering hull material.

These quality factors contribute directly to the grading process, ensuring pistachios meet industry standards for marketing and consumption. The USDA grades pistachios into categories such as U.S. Fancy, U.S. Extra No. 1, U.S. No. 1, U.S. Select, U.S. Artificially Opened, and U.S. Non-Split [1,2,3].

Postharvest Handling and Storage

0-10°C (32-50°F)

Lower temperatures reduce insect activity, mold growth, and deterioration. To prevent lipid oxidation (which results in rancidity) and maintain the quality of pistachio nuts, it is recommended not to exceed 20°C during storage. The lower the temperature the longer the storage life. Pistachios can be stored frozen for a year or longer and remain in good condition [4,5].

Very low respiration, <5 mg CO2/kg-hr at 5°C (41°F), due to reduced water content of the products and the effects of heat during drying on the living status of the tissues [6]

The ideal relative humidity (RH) for pistachio storage depends on the temperature:

At temperatures below 10°C, RH should be maintained between 65–70%.

At temperatures above 10°C, RH should be kept below 32%.

Proper RH is essential to minimize moisture loss, which can cause pistachios to become brittle, and to prevent excess humidity, which promotes pathogen growth and lipid degradation. Maintaining these conditions helps preserve pistachio quality and extend shelf life [5].

Oxygen concentrations below 0.5% (with nitrogen as the balance) or carbon dioxide levels above 80% can help control insects and pathogens and prevent rancidity, staleness, and other signs of deterioration. Using vacuum packaging or nitrogen flushing to eliminate oxygen is recommended for preserving product quality [6].

Disorders

Effective prevention of physiological nut disorders in pistachios begins with proper orchard management; however, environmental and genetic factors also play a role. Maintaining proper irrigation and adequate nutrient levels can help reduce these disorders. Additionally, orchard design— including careful selection of male trees, orchard location, and cultivar choice—plays a crucial role in minimizing disorders. Timely harvesting, careful handling, and proper processing and storage practices are also essential for preventing disorders and preserving nut quality.

Hull Adhesion. Hull adhesion affects pistachio quality by impacting appearance and processing. If the hull doesn’t detach properly during hulling, fragments may remain, requiring removal during sorting. This issue is common in early-split nuts but can also occur in normally split or non-split ones. Factors like nut maturity, environmental conditions, irrigation management, and postharvest handling contribute to hull adhesion. Adhering hulls create conditions for insect attacks and mold growth [1,2].

Figure 2: Adhering hulls in pistachios. This photo shows pistachio nuts with hulls that remain attached to the nuts (adhering hulls). Photo courtesy of Noah X. Kulchin, UC Davis.

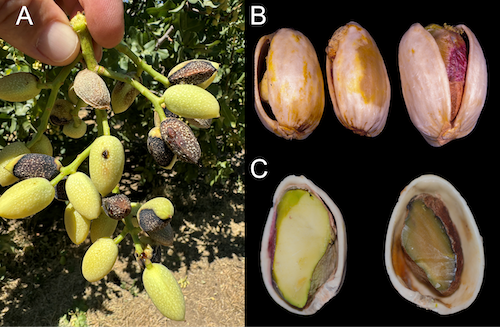

Early Shell Splits (Hull). With normal nut ripening the pistachio splits, and the hull remains intact, protecting the kernel. In early shell splits, which can occur as early as June or July, the hull adheres tightly to the shell and splits along with it, often causing a stain along the shell suture. These nuts are harder to hull than normally split or non-split nuts due to hull adhesion and are more susceptible to fungal contamination. Early splits also expose the kernel to insect damage, increasing contamination risks [1,2].

Figure 3: Early split (hull) pistachios. Photo A shows pistachio nuts with early splitting hulls. Photos B and C show the characteristic stain along the suture caused by early splitting hulls. Photos courtesy of Themis J. Michailides, UC Davis.

Non-splits. Non-split nuts occur when the shell remains closed after harvest, which is undesirable for consumers. These nuts may be immature with smaller lower-quality kernels with poor flavor and texture. Non-split nuts are typically separated during processing, the shells removed and are sold as kernels for snack, cooking or to the commercial ingredient market for use in confectionary, health bars, trail mixes and ice cream [1,2]. These kernels, broken or whole, are often dried but not roasted or salted like the in-shell snack pistachios and are marketed as “raw” pistachios.

Blanks. Blanking occurs when the embryo fails to develop, leaving an empty shell. It can happen during nut set, early shell growth or during nut fill after the shell has fully grown. The reasons are not well defined but poor boron nutrition, irrigation, and crop load competition within a cluster on a single shoot appear to have effects. Blank nuts are lighter, with lower kernel-to-nut ratios, and are removed during processing using a water float tank or air flotation [1,2].

Figure 4: Blank pistachios. This photo shows pistachio nuts with blanks, where the embryo fails to develop, resulting in an empty shell. Photo courtesy of Themis J. Michailides, UC Davis.

Shell Stain . Shell stain, discoloration on the outer shell, is caused by hull breakdown precipitated by early splitting, physical damage, fungal pathogens or environmental factors like sunburn, rain or hail damage. High temperatures and longer intervals during and after harvest and transport and before hulling will significantly exacerbate the hull degradation that produces shell stain. Prolonged storage, especially under high temperatures, exacerbates the problem; cold storage is ideal for preventing staining. Reducing hull damage, while maintaining efficient postharvest handling and processing is crucial for maintaining nut quality and preventing further staining. Washing pistachios after hulling and removing latex can significantly reduce shell staining [1,2].

Figure 5: Shell stain in pistachios. This photo shows five groups of pistachios with varying levels of shell stain: 1 = none, 2 = slight, 3 = moderate, 4 = severe, 5 = extreme.

Odor transfer . Nuts (because of their high lipid content) can easily absorb odors from external sources. Thus, they should not be stored with other commodities that have strong odors.

Ammonia damage . Nuts are very sensitive to ammonia damage which causes blackening of external tissues.

Internal Kernal Disorder (IKD). A dark spreading smear of concentric half circles can appear inside the kernel cotyledons. While the exact cause is unknown, pollen parent and irrigation practices are thought to contribute. Research is ongoing to characterize this disorder.

Figure 6: Kernel stains in pistachio. This photo shows a range of kernel staining in the ‘Golden Hills’ variety of pistachio. Photo courtesy of Themis J. Michailides, UC Davis.

Effective control of pathogens in pistachios starts with proper orchard management to reduce hull disorders, early splits, and insect damage, which create entry points for fungi. Harvesting at optimal maturity, preventing hull and shell damage, and promptly processing pistachios are crucial to minimizing infection risk. Once dried, pistachios should be stored at optimal temperature and humidity to inhibit fungal growth.

Fungal Fruit Rots. Pistachios are vulnerable to endemic fungal pathogens, especially during maturation, harvest, and postharvest handling. Early splitting, insect damage, and environmental conditions promote fungal growth, causing hull and kernel rots and fruit decay. Fungi spread via wind, dust, or rain, peaking during wet seasons, or when relative humidity is >50%. Poor temperature and moisture control in postharvest transit and postprocessing storage will proliferate fungi, leading to shell staining and decay [7,8].

Figure 7: Fungal fruit rots in pistachio. These pictures show an example of fungal fruit rots, in this case caused by Aspergillus flavus. Photos courtesy of Themis J. Michailides, UC Davis.

Aflatoxins in Pistachio. Aspergillus species can cause fruit rot and produce aflatoxins that persist in processed pistachio nuts and pose health risks, primarily liver cancer. In the U.S., the maximum aflatoxin level is 15 ppb, and all shipments must undergo third party testing by USDA-authorized labs. Most infections originate in the field, particularly with early split nuts that expose the developing kernel when hulls are damaged. Late-harvested pistachios tend to have higher contamination levels than those harvested earlier. We recommend harvesting and processing pistachios as soon as they are sufficiently mature, when the percentage of nut split has stopped increasing, to ensure quality and avoid contamination. Transport and processing over 24 hours after harvest significantly increases the risk of contamination [2,9,10].

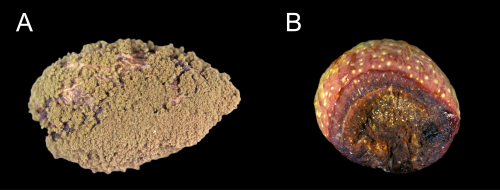

Anthracnose Hull Rot (Colletotrichum spp.) targets pistachio hulls, causing black or pinkish lesions. While it can also affect panicles and leaves, the primary concern is the impact on the nuts and potential losses during postharvest handling. Four species of Colletotrichum have been linked to this disease.

Figure 8: Anthracnose hull rot in pistachios. This photo shows pistachio nuts affected by Anthracnose Hull Rot, caused by Colletotrichum spp. Photo courtesy of Dr. Florent Trouillas, UC Davis.

Insects damage pistachios directly through feeding and indirectly by introducing fungal pathogens. The most harmful pests include navel orangeworm, leaffooted bugs, and redshouldered and flat green stink bugs. Preharvest control is crucial to minimizing and preventing damage, while postharvest methods like low oxygen (<1%), high carbon dioxide (>80%), irradiation, cold storage, vacuum packaging, and nitrogen flushing can reduce insect presence without chemical fumigation [6]. Insect damage can be controlled by following the appropriate prophylactic spray program detailed at: https://ipm.ucanr.edu/agriculture/pistachio/#gsc.tab=0.

Two common types of kernel damage resulting from insects are kernel necrosis and stigmatomycosis, which differ in appearance, severity, and cause:

Kernel Necrosis: Kernel necrosis is caused by direct feeding from large bugs, resulting in dry, localized discoloration that appears brown or black [8].

Stigmatomycosis: Stigmatomycosis is caused by fungal pathogens that enter through insect feeding wounds. Stigmatomycosis leads to wet, slimy decay of the kernel, often accompanied by a stinky, rancid odor and a jelly-like texture. The fungal infection spreads, causing extensive kernel degradation and mold growth. This type of damage not only lowers the nut’s quality but also poses food safety risks due to potential mycotoxin contamination [8].

Specific factors, such as early splitting and hull damage, increase pistachio susceptibility to insect feeding and damage. Timely harvest and proper orchard management can significantly reduce these risks and prevent secondary fungal infections [11].

Figure 9: Insect damage in pistachios. These photos illustrate various forms of insect-related damage in pistachios, which can compromise nut quality and increase susceptibility to fungal infections. Photo A shows pistachio nuts with visible signs of insect feeding damage, including feeding marks, hull damage, and discoloration. Photo B highlights oily nuts, a characteristic symptom of navel orangeworm (NOW) infestation. Photo C shows stigmatomycosis, a fungal infection associated with insect activity, alongside a healthy, uninfected nut for comparison. Photos courtesy of Florent Trouillas, UC Davis (Photo 1) and Themis J. Michailides, UC Davis (Photos 2–3).

References

[1] Crisosto, C. H., & Ferguson, L. (2020). Pistachio. In C. H. Crisosto & G. M. Crisosto (Eds.), Manual on postharvest handling of Mediterranean tree fruits and nuts (pp. 134–160). CABI. https://doi.org/10.1079/9781789247176.0000

[2] Kashaninejad, M., & Tabil, L. G. (2011). Pistachio (Pistacia vera L.). In Postharvest Biology and Technology of Tropical and Subtropical Fruits (pp. 218–247e). Elsevier. https://doi.org/10.1533/9780857092618.218

[3] USDA. (n.d.). Pistachios in the Shell Grades and Standards. Retrieved December 1, 2024, from https://www.ams.usda.gov/grades-standards/pistachios-shell-grades-and-standards

[4] Arena, E., Ballistreri, G., & Fallico, B. (2013). Effect of postharvest storage temperatures on the quality parameters of pistachio nuts. Czech Journal of Food Sciences, 31(5), 467–473. https://doi.org/10.17221/69/2013-CJFS

[5] Tavakolipour, H. (2015). Postharvest operations of pistachio nuts. Journal of Food Science and Technology, 52(2), 1124–1130. https://doi.org/10.1007/s13197-013-1096-6

[6] Kader, A. A. (Ed.). (2002). Postharvest technology of horticultural crops (3. ed). Univ. of California, Agriculture and Natural Resources Communication Services.

[7] Gusella, G., López‐Moral, A., Antón‐Domínguez, B. I., Trapero, C., Polizzi, G., Trapero, A., Michailides, T. J., & Agustí‐Brisach, C. (2024). Current status of pistachio diseases in countries of the Mediterranean Basin. Plant Pathology, 73(8), 2005–2029. https://doi.org/10.1111/ppa.13962

[8] Michailides, T. J., Morgan, D. P., & Doster, M. A. (1995). Diseases of pistachio in California and their significance. Acta Horticulturae, 419, 337–344. https://doi.org/10.17660/ActaHortic.1995.419.56

[9] Esmaeilpour, A., & Shakerardekani, A. (2022). Effect of harvesting time and delay in the hulling process on the aflatoxin content of pistachio nuts. Journal of Food Quality, 2022, 1–4. https://doi.org/10.1155/2022/7831016

[10] USDA. (2024). Importing Pistachios. Retrieved December 1, 2024, from https://www.ams.usda.gov/rules-regulations/section8e/pistachios

[11] Siegel, J. P. (2023). Nut factors associated with navel orangeworm, Amyelois transitella (Lepidoptera: Pyralidae) damage to pistachio (Pistacia vera) in California (2007–2017) and implication for control. Journal of Economic Entomology, 116(3), 882–890. https://doi.org/10.1093/jee/toad051