Maturity and Quality

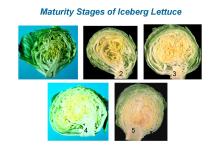

Maturity is based on head compactness. A compact head which can be compressed with moderate hand pressure is considered ideal maturity. A very loose head is immature and a very firm or hard head is overmature. Heads that are immature and mature have much better flavor than overmature heads and also have fewer postharvest problems.

After trimming outer wrapper leaves, the leaves should be a bright light green color. Leaves should be crisp and turgid.

Postharvest Handling and Storage

0°C (32°F) is required to optimize lettuce storage life. A shelf-life of 21-28 days can be expected at this temperature and RH. At 5°C (41°F) a shelf-life of 14 days can be expected as long as no ethylene is in the environment. Vacuum cooling is usually used for iceberg lettuce, but forced-air cooling may also be used successfully.

Freezing Injury. Freeze damage can occur in the field and cause separation of the epidermis from the leaf. This weakens the leaf and leads to more rapid bacterial decay. During storage, freeze damage can occur if the lettuce is stored at at <-0.2°C (31.7°F). This appears as darkened translucent or water-soaked areas that will turn slimy and deteriorate rapidly after thawing.

Iceberg lettuce heads have moderate respiration rates:

| Temperature | 0°C (32°F) | 5°C (41°F) | 10°C (50°F) | 15°C (59°F) | 20°C (68°F) |

| ml CO2/kg·hr | 3-8 | 6-10 | 11-20 | 16-23 | 25-30 |

To calculate heat of production multiply ml CO2/kg·hr by 440 to get Btu/ton-day or by 122 to get kcal/metric ton-day.

Iceberg lettuce is extremely sensitive to ethylene. Russet spotting (see physiological disorders) is the most common symptom of ethylene exposure.

>95%

Very low,

Some benefit to shelf-life can be obtained with low O2 atmospheres (1-3%) at temperatures of 0-5°C (32-41°F). Low O2 atmospheres will reduce respiration rates and reduce the detrimental effects of ethylene. Intact heads are not benefited by atmospheres containing CO2 and injury may occur with >2% CO2 (see Physiological Disorders, brown stain). Lettuce cut for salad products, however, is commonly packaged in low O2 (<1%) and high CO2 (10%) atmospheres because these conditions control browning on the cut surfaces. On salad pieces, cut surface browning occurs more rapidly and more extensively than do symptoms of brown stain caused by CO2.

Temperature & Controlled Atmosphere Photos

Disorders

Title: Ethylene-induced Russet Spotting

Photo Credit: Adel Kader, UC Davis

Bacterial soft-rots are caused by numerous bacteria species and result in a slimy breakdown of the infected tissue. Soft-rots may follow fungal infections. Trimming outer leaves, rapid cooling and low temperature storage reduce development of bacterial soft-rots.

Fungal pathogens. May also lead to a watery breakdown of lettuce (watery soft-rot caused by Sclerotinia or gray mold rot caused by Botrytis cinerea) but are distinguished from bacterial soft-rots by the development of black and gray spores. Trimming and low temperatures also reduce the severity of these rots.